How to Ship Bulk Cargo With FIBC Bags

During your business operations, you may often need to ship bulk cargo like sand, gravel, seeds, grains or coffee beans. One excellent method is to use flexible intermediate bulk containers (FIBCs). These dependable bulk bags make loading and transporting bulk goods quick, easy and safe.

For instance, FIBCs are by far the preferred method of shipping dry bulk materials aboard seagoing vessels. They are easy to handle, so they make loading and unloading quick and convenient. They are light, so they allow you to ship more of your product by weight. They are also easy to secure so that they don’t pose a hazard by shifting in transit.

What are some best practices for shipping bulk cargo with FIBCs? This guide discusses how to load, stack and palletize FIBCs, as well as how to ensure safety and get the most value for your money.

How to Load FIBCs

To get the most out of your FIBCs, you need to know how to load them correctly. Below are several recommended steps to follow to make the shipping of big bags safe and effective:

- Follow the manufacturer’s recommendations: Your FIBCs will likely come with clear manufacturer’s recommendations for weight limits and general use. Be sure to read those recommendations and follow them precisely. Doing so will help you protect your products and ensure safety for everyone who handles your bulk bags.

- Stack only FIBCs designed for stacking: Stacking your FIBCs helps you save space so you can ship more products at once, increasing your efficiency and profitability. If you use baffled bulk bags, which maintain a consistent square shape, you can maximize even more space. However, be sure you stack your FIBCs only when you know their design permits safe stacking. Otherwise, they may present spillage or safety hazards.

- Ensure secure, even distribution: As you prepare your bulk bags for transport, make sure they remain stable. Otherwise, they could topple over, spill and potentially injure someone. Unevenly distributed bags could also destabilize the transporting vehicle or vessel, moving its center of gravity and making it more vulnerable to accidents or capsizing. Secure your bags tightly, or consider filling any empty spaces with airbags to ensure that your FIBCs stay in place.

- Choose forklifts over cranes: Consider using a forklift instead of a crane to move your bags. Because a forklift uses a smooth motion rather than a swinging motion, it will keep the bags safely away from the vehicle’s side, where they could scrape or catch and tear open. Using a forklift also helps prevent sudden stops and jerks that could spill the bags.

- Keep FIBC holding areas clear of debris: Whenever FIBCs will be on a flat surface like a dock between loading and transport, ensure the area is clean before placing the bags down. That way, you’ll know they won’t tear and spill.

- Use all available loops: Different types of FIBCs have different numbers of lifting loops. Many have four, while others have only one or two. As you lift your FIBCs to load them into a truck or vessel, be sure to use all the loops on the FIBC. Missing a loop with the forklift or loader hook can lead to dangerously uneven weight distribution and cause your bags to fall. Using all the loops ensures structural integrity and stability.

Remember that using FIBCs to ship cargo is much different from using other containers and comes with specific advantages and requirements. FIBCs are light, whereas other containers can add cumbersome extra weight. FIBCs often have open tops, so you may need to cover them securely. FIBCs are also flexible enough that you can stack, squeeze and rearrange them to get the most out of your storage space. Remember to do so correctly, though, to keep personnel safe and protect your products from spills and damage.

Stacking and Palletizing FIBCs

To get the most benefit from your bulk bags, you’ll also need to know how to stack and palletize them properly. Before we discuss the correct steps for stacking and palletizing your FIBCs, let’s first define these two terms.

- Stacking: Stacking involves arranging your FIBCs on top of one another without any additional structures. Using stacking without pallets helps you reduce costs, save space and minimize waste.

- Palletizing: Palletization involves securing your FIBCs on top of wooden, plastic or metal pallets. Palletization gives your bulk bags a bit more stability during transport.

Whichever method you choose, the way you stack and palletize your bulk bags will also depend on your chosen shipping method and the types of bags you have. For instance, bags in the hold of a ship might do fine with stacking, while those exposed to the elements might require pallets for greater security. Bags with complex or rigid spouts might also be more challenging to stack.

Stacking

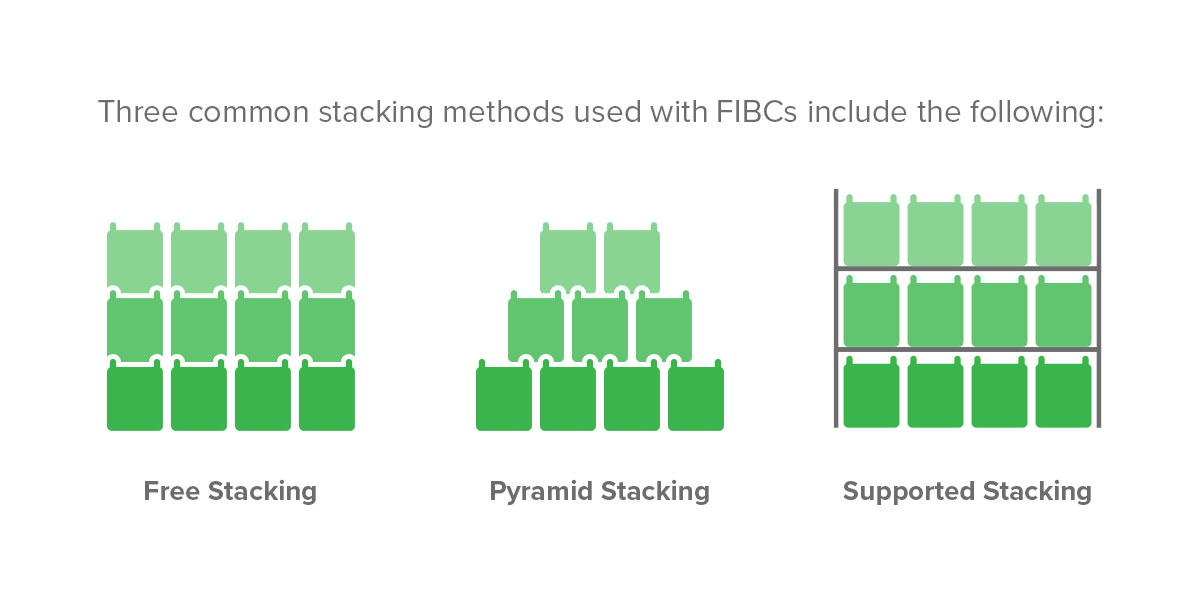

When you double-stack your FIBCs, you need to use the recommended techniques to protect the products in your bags and ensure safety for everyone around them. Three common stacking methods used with FIBCs include the following:

1. Free Stacking

Free stacking involves placing your bulk bags on top of one other without using nearby structures for support. For safety, you’ll usually need to use the targeted style of free stacking known as pyramid stacking.

Use free stacking only with materials you are confident can withstand the weight in the bags above them. The lower bags will bear the full weight of the bags above, and they could become crushed if the products in them are fragile.

2. Pyramid Stacking

Pyramid stacking is ideal in a wide range of applications because of the stability and safety it offers. This method involves stacking FIBCs in a pyramid-shaped structure, with larger layers of bags at the bottom and smaller layers at the top. This tiered structure allows the bottom layers to support the weight of the top layers more easily and reduces the likelihood of fallen bags.

As you perform pyramid stacking, you’ll need to make sure each FIBC in the upper layers rests on four different FIBCs in the layer directly below. Adhering to this best practice allows you to maintain an even bag distribution. It also gives each bag a stable platform to rest on and ensures no FIBCs will slip through the gaps between the lower bags.

3. Supported Stacking

Supported stacking is another highly preferred method of stacking bulk bags. It involves using external structures like side walls to hold your FIBCs in place. If you use this method, you’ll place your bags in even rows between the walls of a trailer or storage compartment, taking care to minimize or fill in any gaps. You can then place additional layers of FIBCs on top.

Supported stacking is beneficial because it dramatically reduces the extent to which your bulk bags can shift. It helps you keep your FIBCs securely in place to prevent tumbles and spills.

Palletizing

The use of pallets with FIBCs is common both because of the security and stability it provides and because it makes loading and unloading your bags much faster and easier. It is an ideal option if stacking your bags is impractical. Because the pallets are bulky, this option is not always feasible if you have limited space, though — for example, if you need to load dozens of FIBCs into a modest-sized truck.

As you secure your bulk bags to pallets, you’ll generally use one of two methods:

- Banding: One option is to keep your FIBCs securely in place using sturdy plastic or metal bands. The rigid bands keep your FIBCs from moving, so this method is highly effective, though it can be more expensive.

- Pallet wrappers: Another excellent option is to use pallet wrappers or stretch wrapping. Wrappers offer an easy, economical option for keeping your bulk bags secure.

When you use either bands or pallet wrappers, be sure these protective items are securely in place before you start loading your FIBCs.

Safety Considerations

When you’re thinking about how to ship cargo overseas with FIBC bulk bags, safety considerations are crucial, especially for shipments by vessel. The National Insititute for Occupational Safety and Health (NIOSH) reports that employees at port operations and marine terminals have higher injury and fatality rates than other employees across the United States. From 2011 to 2017, these workers became injured at a rate nearly double that of the overall U.S. workforce. Your company can help reduce these figures by following some best practices for your pallets.

Handling your FIBCs carefully has direct benefits for your company as well. It extends the bags’ longevity, so you can get more use out of them before purchasing new ones.

As you prepare your FIBCs for shipment, you’ll need to keep several safety considerations in mind. You should follow safety practices and take a few precautions.

1. Things to Do

Below are some advisable ways to handle your FIBCs:

- Maintain a clear line of sight at all times when you’re moving bags.

- Make sure all forklift tines, loading hooks and other loading tools are free from sharp, jagged edges.

- Ensure all lift loops and sleeves remain vertical during lifting. Adjust forklift tines as necessary to prevent lateral force damage.

- Make sure employees stand clear of any safety hazards.

- Stack only FIBCs designed for stacking, and ensure their stability before adding more bags.

- Use the pyramid and supported stacking methods whenever possible.

- Protect your bulk bags against UV damage by shielding them from direct sunlight.

- Arrange bulk bags in a configuration that will minimize shifting in transit.

2. Things to Be Careful About

Below are some precautions to take with your bulk bags:

- Never lift a filled FIBC without using all its loops or sleeves.

- Never permit employees to stand with any part of their bodies under a suspended bag.

- Never push or drag FIBCs along the ground.

- Never fill a bulk bag with a weight that exceeds its safe working load.

- Never fill bulk bags with combustible materials not meant for those types of FIBC bags. Examples of bulk bag types suitable for combustive materials include type C and D — always check with the manufacturer or supplier before using these bags to ensure correct operation.

- Never move a bulk bag without a clear line of sight in the direction you are moving.

- Never leave bulk bags exposed to excessive amounts of direct sunlight.

- Never attempt to move FIBCs without first removing any bags stacked on top of them.

Fortunately, FIBCs are generally much safer and easier to use for bulk shipments than most other types of containers, especially for long ocean journeys. Because they are so light, they add very little dead weight to your shipments, so they can ship large volumes of products. Because they are convenient to move with machinery, they are also often easier to load and safer for personnel to work with than solid overseas shipping containers that sometimes require manual handling.

FIBC Bags Reduce Shipping Costs

One of the most significant advantages of using FIBCs for your bulk shipments is how much they can save you on your shipping costs. Their cost-to-weight-transported ratio is incredibly low, so you’ll get tremendous value out of using them. FIBCs can help you save money during shipping in a few different ways:

- Reducing transportation fees: Most shipping companies charge by total weight, including containers. Fortunately, bulk bags add very little dead weight to your overall shipment. Unlike bulky, intermodal shipping containers, FIBCs are light enough to incur very minimal extra fees, so most of your shipping expenses will go directly toward moving your products.

- Maximizing carrying capacity: Most bags have a safe working load of 1,000 to 5,000 pounds. Even if you have a large, heavy shipment, you may need to purchase only a few FIBCs to get it to its destination.

- Saving storage space: Part of how bulk bags are shipped involves storage en route. Bulky intermodal containers might take up significant extra warehouse space and cause you to incur additional fees. Compact bulk bags, on the other hand, take up very little space, so they allow you to rent less space and reduce your expenses.

If you use reclaimed bulk bags instead of brand-new bulk bags, you’ll save even more. Recycled bags tend to be more economical choices than brand-new bags while providing the same high performance and dependability, and you can often use them multiple times, reducing your costs even further. Buying FIBC bags in bulk is also an outstanding solution because you can often receive lower prices the more bags you buy.

To get specific information on the costs of bulk bags and exactly how much they can save your organization, you’ll likely want to speak to a bulk bag supplier. The professionals will have the industry expertise to fill in the correct details for your unique business practices.

FIBC Bulk Bags From Bulk Bag Reclamation

Whether you need bulk bags for an agricultural operation, a construction business, a mining company, or any other business that regularly makes bulk shipments, let Bulk Bag Reclamation be your trusted source.

When you choose reconditioned bulk bags, you gain several financial and logistical advantages for your business. Since bulk bags are lightweight and economical, your carrying quantities will soar while your dead weight remains low. You’ll maximize your shipping space for overseas transport so you can ship more products, make more customers happy and realize more profits.

Because of their lightness, ease of use and post-consumer composition, recycled FIBCs are practical, cost-effective and eco-friendly, helping you do your part to help reduce the 82.2 million tons of packaging and containers that end up in U.S. landfills each year. They are some of the best options for shipping bulk cargo around the world.

Request a quote today, or contact us to get started with purchasing reconditioned bulk bags.